Combination Printing

In short, hybrid printing is combining several printing technologies and converting techniques in a single-pass process. It aims to merge the capabilities of conventional and digital printing methods, for example integrating the reliability, efficiency and in-line features of flexo printing with the creative possibilities of digital printing. Hybrid printing enables you to serve a larger part of the market segment because you can combine several printing techniques and utilize the advantages. For example, in flexographic printing you can’t print variable data, and you can’t do cold foil in digital. With hybrid printing, you can do both.

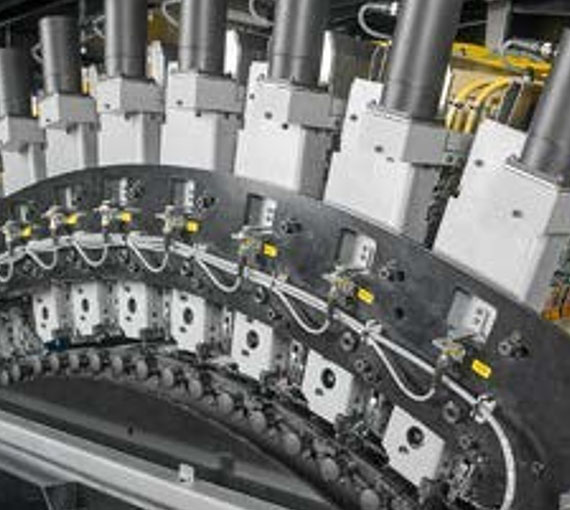

This technology allows us to run higher volumes than other digital presses with many different kinds and variable data with minimum tooling costs associated. Rapid labels installed the first Gallus Labelfire 340 digital production system in the southern hemisphere and this enabled us to achieve levels of print quality that match those of high-resolution offset printing. This is reflected in the native (physical) resolution of 1,200 × 1,200 dpi with a droplet size of just 2 pl and up to 200 grey scale values, corresponding to a visual resolution of 2,400 × 2,400 dpi.

The high physical resolution of the inkjet heads offers a real advantage, particularly when it comes to small symbols and characters as well as fine lines and gradients down to zero percent.