Food Packaging

Food Packaging

Food Packaging

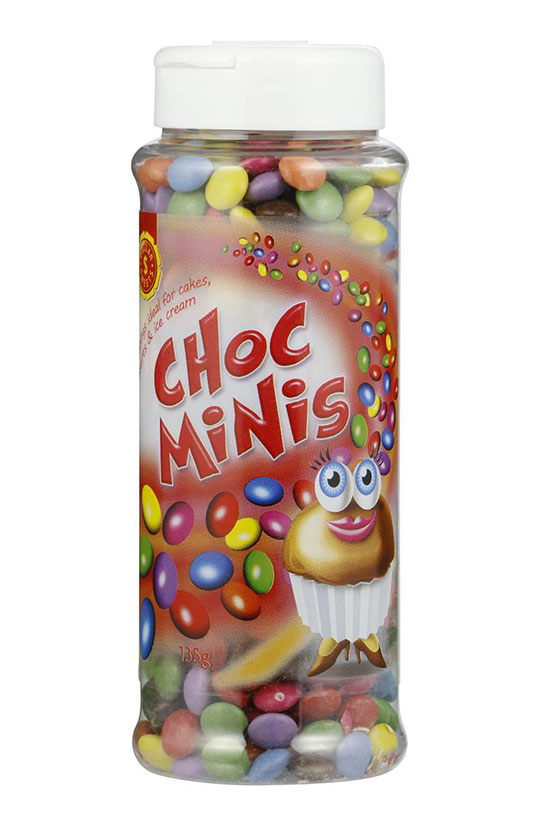

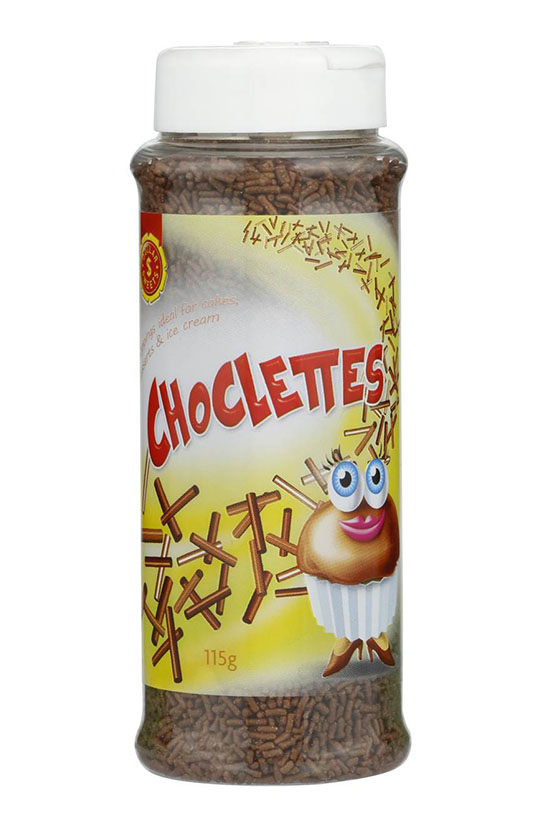

Food packaging comes in a wide variety of packaging from Jars, bottles ,cans, cartons and everything in between.

Rapid labels will guide you every step of the way to ensure you have the right adhesive and finish for you label packaging.

We stock a large variety different material to suit all applications.

Adhesive Options

Hotmelt Adhesive

ot melt adhesives are generally rubber based adhesives that have a high initial tack. When pressure is applied to the adhesive and it is in contact with a surface, the adhesive will begin to “cure” and grip the surface it is applied to. The adhesive is softer compared to acrylic adhesives and as such can bleed into rough surfaces like recycled cardboard to provide excellent adhesion on non-smooth surfaces. As they are rubber based they have poor resistance to high temperatures and UV light and as such should not be used outside for extended periods.

Acrylic adhesive

Acrylic adhesives are chemically different to hot melt adhesives and have good UV and heat resistant properties. When pressure is applied to the adhesive and it is in contact with a surface, the adhesive will have a lower initial tack compared to the hot melt but over the next 24 hours the adhesion will grow to a high level. As the adhesive is not as soft as the hot melt it does not perform as well on rough surfaces like recycled cardboard. Due to its harder composition acrylic adhesives are more user friendly for conversion and application as the adhesive has less tendency to flow outside the edges of the label.

Freezer grade

Freezer grade label adhesive are the smart choice for a range of applications including meat packaging, medical products, cold beverage storage, and common packaging substrates used in freezer conditions.

Face stocks

Polypropylene labels

Polypropylene (PP) labels are a widely used alternative to vinyl labels. They offer all the strengths of a synthetic material but have a lesser impact on the environment than vinyl and are recyclable through local government recycling programs. Polypropylene labels are also a proven and widely used alternative to paper labels as they are waterproof and more durable than paper labels.

Polyethylene labels

A milky white synthetic film with light and flexible properties, unlike polypropylene it can stretch in all directions so it’s perfect for labelling products that expand and contract within the maximum operating temperature of 204°C. Polyethylene useful for strong tamper evident seals on lids, cosmetic tubes and electrical items.

Direct thermal labels

Direct thermal material has a chemical layer applied to the adhesive that is activated by heat.

Direct thermal labels allow you to print variable information on the Pre-printed/blank labels

Thermals transfer labels

Thermal transfer materials works slight different to direct thermal.

The variable data printing is transferred onto the label by way of Ribbon this enables you to use a larger variety of material such as gloss paper and gloss polypropylenes.

The print head elements heat up and cause the ribbon to transfer onto the label surface.

Metallic labels

Metallic label stocks are a cost-effective subsite for a foil finish.

This can be used for a wide variety of applications where a demanding label substrate is required, from water, food & beverage, household, chemical and point of sale label.

Crystal Clear

Crystal Clear is a clear Polypropylene top coated film designed for label clarity with exceptional “no label” effect. Supplied with good stability to allow optimum print results and label performance giving the stock a cloud free/high resolution finish.